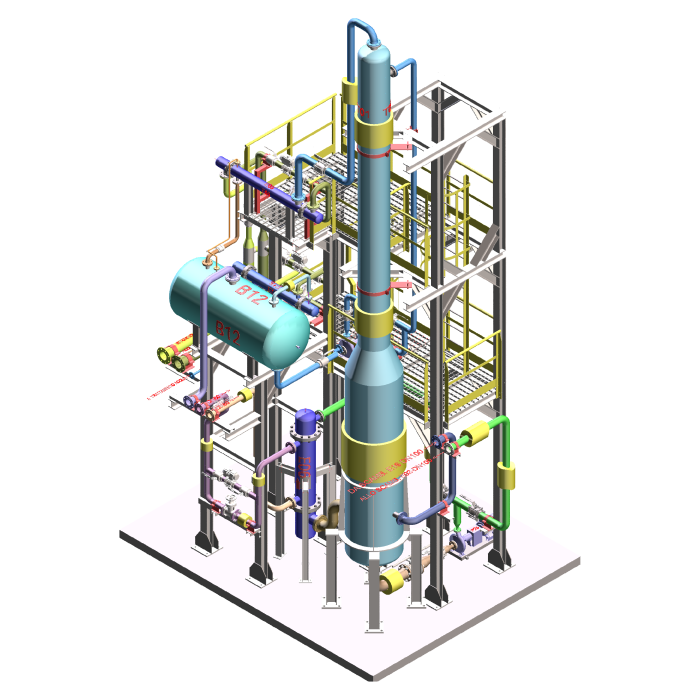

Oil & Gas and Petrochemical plants

Dimont Impianti is an ISO 9001:2015 certified engineering company, operating in the oil & gas, petrochemical, chemical and energy sectors, focused on project management from the process development phase to basic and detailed design, procurement, construction, commissioning and start-up.

On large projects, DIMONT IMPIANTI works with partner engineering companies and constructors, using a team of highly qualified and multidisciplinary engineers and technicians capable of developing complex plants in the oil and gas sector and in particular in the three sectors after extraction concerning Upstream, Midstream and Downstream.

Oil & Gas Plants: the three sectors of extraction and production

Upstream sector

The Upstream sector includes all the stages of crude oil extraction for the recovery and production of crude oil and natural gas. In particular, Dimont is able to completely design all the stages of the oil treatment process of an oilfield from the multi-well extraction manifold to gas separation, sludge removal, water removal, desalination and desulfurization. After this stage the crude oil is ready for transport and export.

Midstream sector

The Midstream sector covers everything related to the transportation and storage of crude oil and natural gas prior to its transformation into fuels. Dimont has the know-how to follow the general contractor in the complete design of oil loading terminals, LNG, pumping networks and oil flow stations.

Downstream sector

The Downstream sector covers all the stages of oil refining for the production of petrols, diesel oil, fuel oils, waxes, asphalt. petrochemicals, fertilizers, etc.

Dimont Impianti: the petrochemical processes developed

Dimont is able to develop the basic and detailed design, follow the procurement of materials, supervise the assembly and commissioning of all refining units after the general contractor has purchased the necessary process licences. Dimont provides added value to the development of basic and detailed design by seeking targeted technological solutions that significantly improve the capacity and energy efficiency of the sections of the plant, which are in any case already equipped with modern technology.

-

Our experience to develop engineering in the following Oil and gas and petrochemical processes:

- Complete biomass hydrocarbon plant

- Wax plant

- Process units (topping-vacuum)

- Refinery offsites

- Blending lubricating oils - Blending greases

- Crude desalters

- Fuel oil treatment

- Sulfur recovery and amine regeneration

- Mercaptan oxidation

- Oil/gas separation

- Gas softening

- Filtration and separation of natural gas

- LPG storage and handling

- Oil products storage terminal

- Lubricating oil deparaffining plants

- Biodiesel production processes

- Syngas production process

- Biological treatment plants (sludge production and drying)